ABOUT US

RSA specializes in the use of passive acoustics to inspect, diagnose—and in some cases remediate—underwater & deepwater petroleum infrastructure and all associated pressure-containing & active-flow components. Our services are most often employed concurrently with hydrotesting during or following completion, refurbishment, repair, and commissioning operations, where we rapidly locate & define problems, and corroborate integrity. As a measure of the degree trust our clients place with us, RSA is often mobilized to, or prepositioned near, the field location of interest, and asked to standby, at varying degrees of readiness, in case an issue arises.

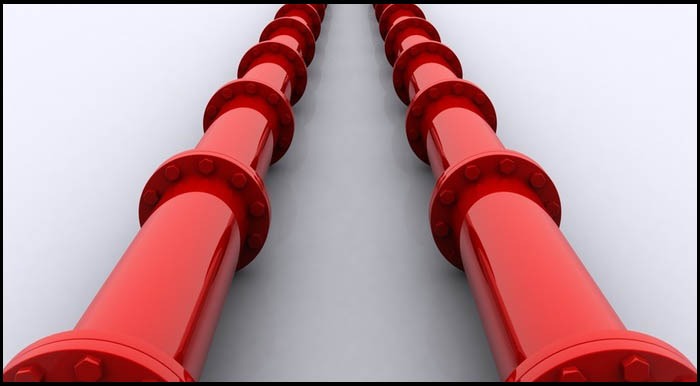

Our services have proven effective with virtually all subsea petroleum infrastructure components, including valves, pipelines, risers, and couplings, including concealed & internal items. They are also used to assist & intervene with operational (i.e., product-containing) installation issues, such as whether a valve is thru-leaking or sealed, and predicting the location of internal obstructions, as with stuck pigs.

RSA methods are deployed via ROV or diver (Flocator), or when appropriate, in a ship-towed mode (Towcator). RSA technology provides rapid results, typically outperforming diver, video-inspection & dye methods, & overcomes various operational complications & costs inherent in such conventional approaches. Apart from inspecting discrete components, Flocator is well-suited for use during pipeline video-flyover surveys. Towcator has been successful whether deployed alone or in tandem in with side-scan sonar. In certain scenarios, RSA has provided rapid solutions unattainable by any other known methods or service providers, avoiding any need to disassemble & recover subsea components for inspection and replacement.